Anchoring Adhesive

The anchoring adhesive, also known as chemical anchoring adhesive or rebar anchoring epoxy, is designed for post-installed reinforcement in concrete and masonry structures. It is widely used in applications such as structural retrofitting of buildings, bridges, subways, tunnels, and highways, as well as in connecting new and old structural elements, or reinforcing steel and timber components.

Compared to traditional methods like threaded connections or welding, chemical anchoring with epoxy adhesive offers significant advantages. It allows for faster installation with minimal equipment, reducing labor and material costs. The adhesive forms a strong chemical bond between rebar and concrete, improving seismic resistance and overall structural integrity. In addition, it offers outstanding durability and weather resistance, maintaining performance even in harsh environments.

-

- Chemical Anchoring Adhesive, MT-500 Chemical anchoring adhesive is a high-performance two-component adhesive with epoxy and hardener, developed for modern structural reinforcement, retrofitting, and anchoring applications. Packaged in a durable dual-cartridge system and applied through a static mixing nozzle, the adhesive ensures thorough and consistent on-site mixing. Full Details

-

- Fast Curing Anchoring Adhesive, MT-500 Developed for time-critical applications, the fast-curing anchoring adhesive is formulated to accelerate installation schedules without compromising performance. Ideal for sectors such as rail maintenance and emergency infrastructure repair, this structural adhesive reaches load-bearing strength in just 2 hours at 25-30°C, significantly improving onsite efficiency. Full Details

-

- High Strength Anchoring Adhesive, MT-390/360 This high strength anchoring adhesive is a two-component epoxy system, designed for structural reinforcement, steel connection anchoring, and equipment base fixing. Supplied in a dual-cartridge format and dispensed through a static mixing nozzle, the adhesive ensures uniform blending for reliable performance. Full Details

-

- Modified Epoxy Anchoring Adhesive, MT-T100 The modified epoxy anchoring adhesive is a chemically reactive, high-performance bulk bonding system, designed for use in large-scale rebar anchoring and dowel installation. Supplied in pail form for on-site mixing, the adhesive features a smooth, workable consistency that allows for easy blending and application. Full Details

-

- Underwater Anchoring Adhesive, MT-500/W The underwater anchoring adhesive is a two-component injectable epoxy system, designed for reliable anchoring of threaded rods, rebar, or anchor bolts in wet, humid, or fully submerged concrete environments. Dispensed through a static mixing nozzle using a standard applicator, the system ensures accurate on-site mixing and easy installation, even in challenging conditions. Full Details

-

- Heat-Resistant Anchoring Adhesive, MT-500/H The heat-resistant anchoring adhesive is a two-component epoxy anchoring system, supplied in a rigid cartridge and dispensed through a static mixing nozzle for consistent and easy on-site application. Formulated for thermal stability, this adhesive is suitable for long-term service at temperatures up to 135°C, and can withstand short-term exposure up to 200°C (≤3 hours). Full Details

Mankate provides two main types of anchoring adhesives: inorganic-based formulas and epoxy-modified systems. Inorganic anchoring adhesives, made from silicate cement, special additives, and retarders, are economical and easy to apply, but they offer lower strength and limited durability. As a result, they are often restricted in critical applications such as nuclear, transportation, and industrial infrastructure.

In contrast, epoxy-based anchoring adhesives are formulated with high-purity resins and hardeners, offering superior tensile and shear strength, excellent aging resistance, and high fatigue tolerance. Their thixotropic nature ensures ease of use across vertical, overhead, or deep embedment conditions. These adhesives are widely used, and often specified, for high-performance projects in nuclear energy, metro systems, high-speed rail, bridges, and industrial plants, where strength, safety, and long-term reliability are non-negotiable.

At Mankate, we place strong emphasis on long-term collaboration across industries and continue to expand our global reach through trusted partnerships. Our structural strengthening materials and anchoring products have been successfully applied in over 50,000 engineering projects worldwide, spanning residential and commercial construction, bridges, tunnels, railways, petrochemicals, and nuclear power.

- 20Years of industry experience

- 100Years long product lifespan

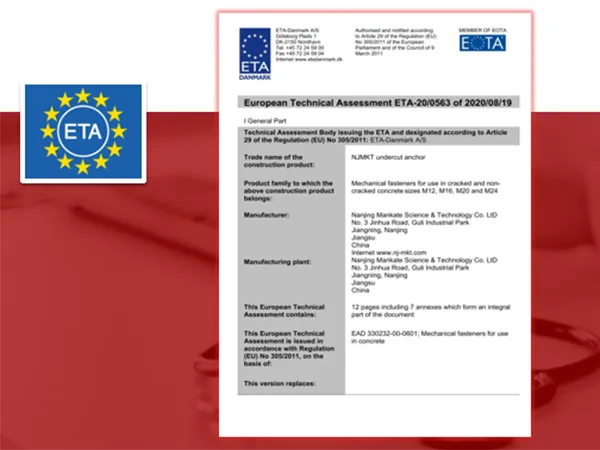

- ETA Certified to meet European standards

- 50,000+ Customer cases with proven results